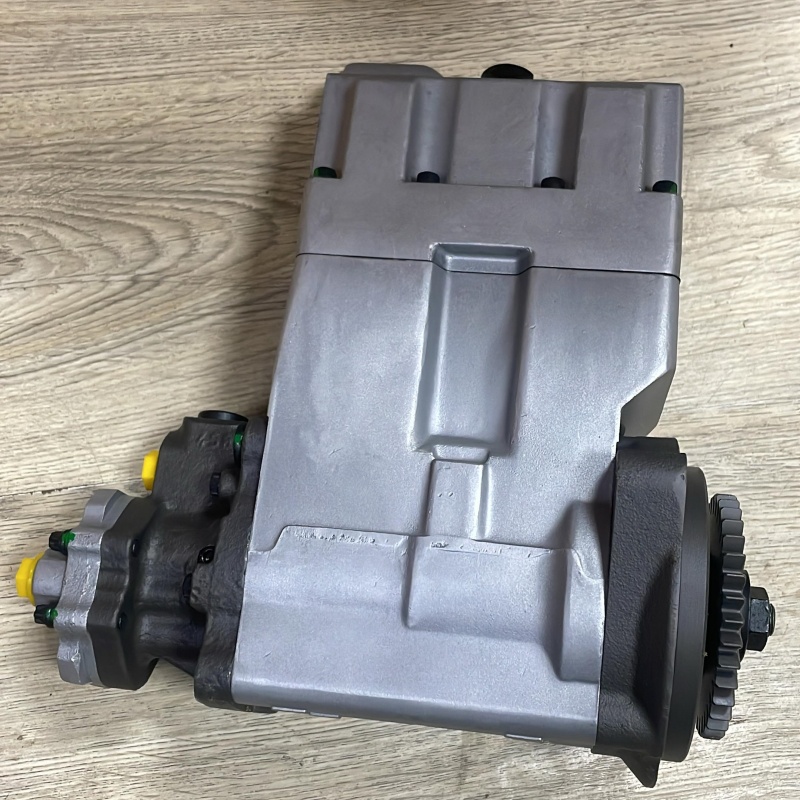

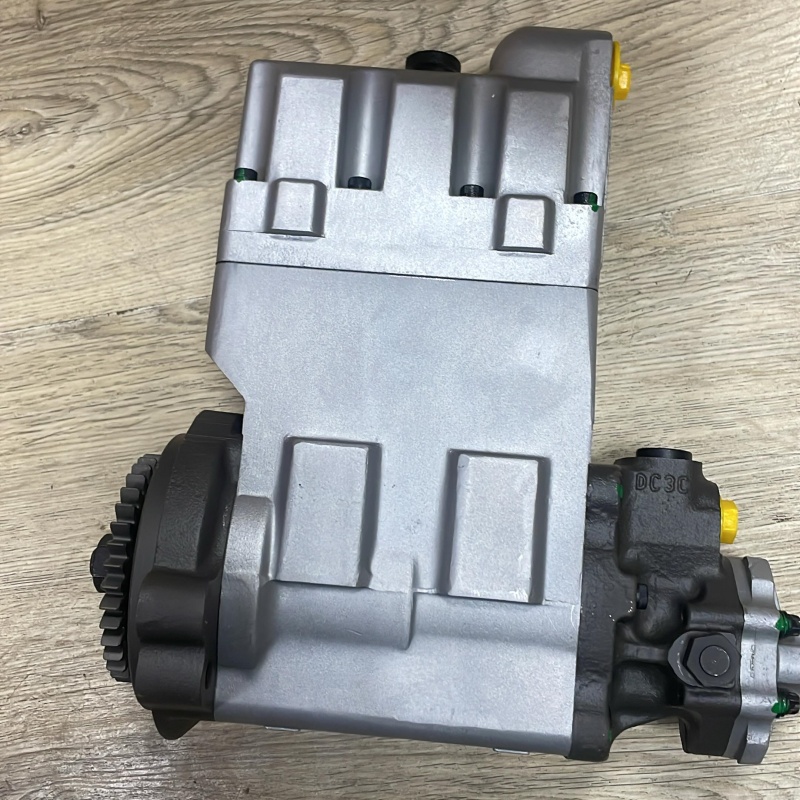

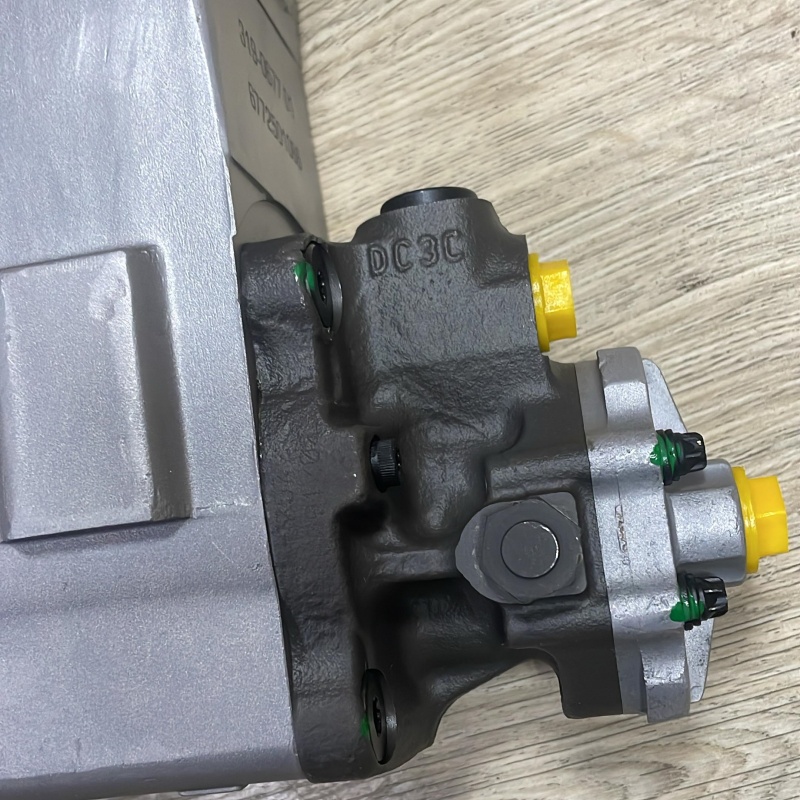

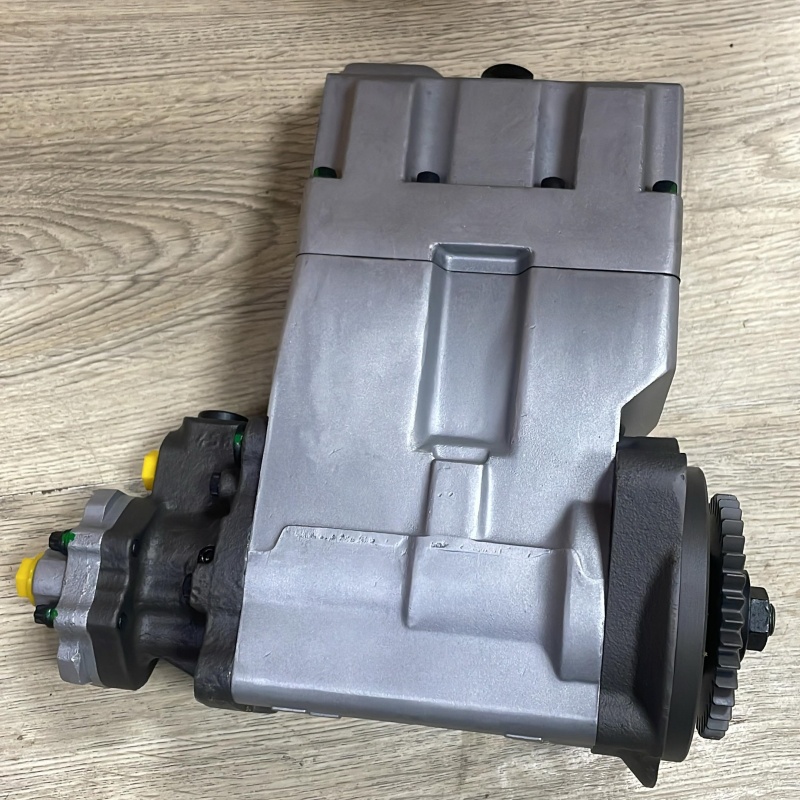

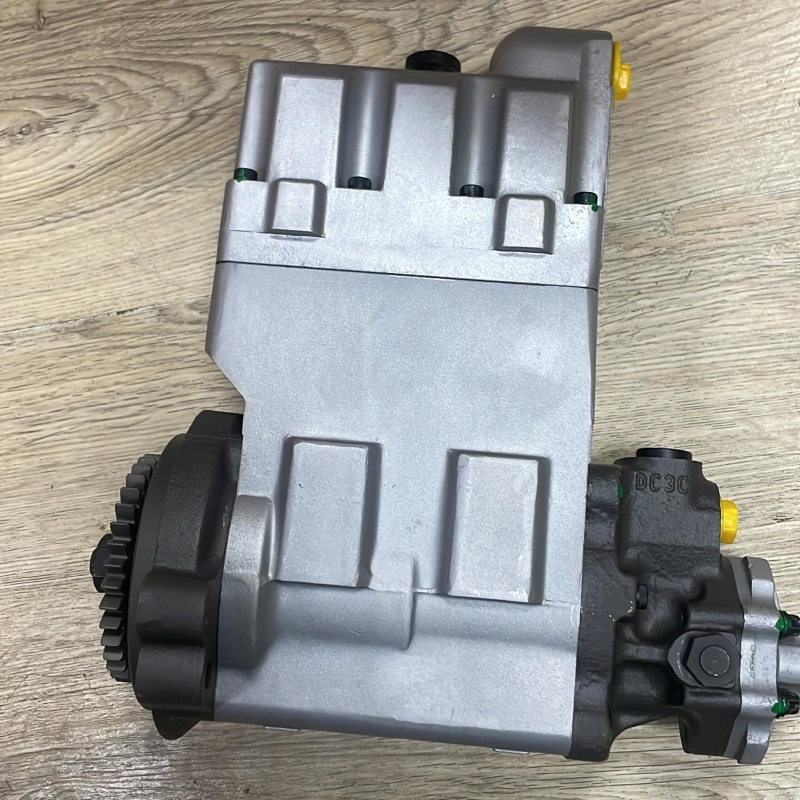

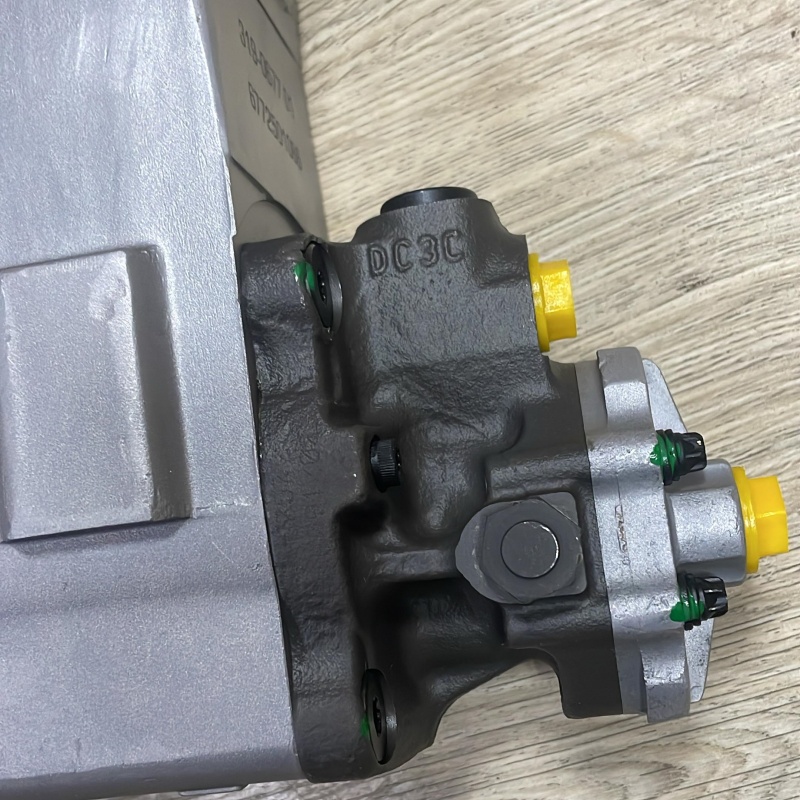

Caterpillar 319-0677 High pressure fuel pump C7.1

1. Accurate adaptation to working conditions: taking into account complex working conditions, such as severe frosts and large loads in Russia, the system is adjusted in accordance with the main models of Carter engines to guarantee that high -pressure fuel pump can steadily supply oil in harsh conditions and ensure the effective operation of the engine.

2. High wear resistance and frost resistance: made of high -quality frost -resistant materials and processed using special technology, it can accurately spray oil at low temperatures, has excellent wear resistance, withstands high loads, reduces the number of refusals and extends the service life.

3. Convenient repairs and maintenance: the design is modular, the parts are highly universal, and the maintenance staff can easily use it. Parts are easy to replace, and service can be quickly performed in remote areas of Russia, which reduces downtime and service costs.

Product representation

1. Detailed product information

1. Review of the product

Caterpillar fuel pumping pumps are specially designed for Caterpillar series engines. They are the main components of the fuel injection system. Their performance is directly related to the output power of the engine, fuel economy and emissions. High pressure fuel pump can accurately control the amount and time of fuel injection, guaranteeing the effective and stable operation of the engine in various operating conditions. Whether it is construction sites, mining or long -range transportation, it can provide Carter engines with reliable fuel supply.

(II) The principle of work

High pressure fuel pump forces the plunger to make reciprocating movements through the camshaft. When the plunger moves down, the fuel is absorbed into the pump chamber from the oil inlet; When the plunger moves up the fuel pressure in the pump chamber increases. When the pressure exceeds the opening pressure of the oil exhaust valve, the oil exhaust valve opens, and the fuel is sprayed into each engine cylinder through the high pressure oil tube. The fuel supply by an injector pump is determined by the effective stroke of the plunger. By changing the effective stroke of the plunger using the adjusting mechanism, you can accurately control the amount of injected fuel.

(III) product characteristics

High -precision production: the use of advanced processing technologies and precision equipment guarantees that the accuracy of the size and the correspondence of each component of the high pressure fuel pump are extremely high. For example, the gap between the plunger and the plunger’s sleeve is regulated in extremely small limits, which ensures the tightness of the fuel and the stability of the injection pressure, making the fuel injection more accurate, thereby increasing the efficiency of combustion in the engine and reducing fuel consumption.

Excellent reliability: the main components are made of high -quality materials and undergo strict heat treatment, which provides excellent wear resistance and fatigue strength. In harsh working conditions, such as high temperature, high pressure and high dusting, it can still work stably, reducing the frequency of failures, extending the service life of the equipment, as well as reducing user expenses for maintenance and downtime.

The function of flexible adjustment: equipped with an improved mechanism for adjusting the amount of oil, which allows you to flexibly adjust the amount of injected fuel in accordance with various engine operating conditions, such as idle, acceleration, full load, etc., due to which the engine always supports the best working conditions. At the same time, the moment of injection of high pressure fuel pump can also be accurately adjusted to adapt to the requirements of combustion of various engines and further optimization of engine performance.

Adapts to various types of fuel: it can adapt to fuel of different quality, including fuel with a high sulfur content, and has good compatibility. Due to the optimization of the internal structure and the choice of materials, wear and corrosion of fuel impurities on the injector pump are effectively reduced, which ensures its normal operation even with uneven quality of fuel, which provides greater convenience for users.

2. The installation method

1. Preparation before installation

Checking the correspondence of the model: Carefully check whether the model of the CARTER engine is fully consistent with the Model of the Carter engine to make sure that the technical characteristics and parameters of the TNVD comply with the engine requirements. At the same time, check the appearance of the high -pressure fuel pump to make sure that there are no damage, deformations, strokes, etc., that the connecting parts are not weakened and that there are no missing internal parts.

Preparation of tools and materials: Prepare professional installation tools, such as wrenches, heads, dynamometric keys, sealants, etc. Make sure that the accuracy and quality of the tools meet the requirements for installation, as well as use sealants that are resistant to high temperatures and oils suitable for the fuel system. In addition, for the initial commissioning after installation, pure fuel should be available.

Cleaning: thoroughly clean the seat of the high -pressure of the engine, the connecting tubes and the high -pressure fuel pump itself using a cleaning agent to remove oil, pollution, rust, etc., and make sure that the installation surface is clean and smooth. In particular, the sealing surface of the seat should be carefully checked for scratches and damage. If necessary, repair or polish it to ensure good tightness.

(II) Stages of installation

Positioning during installation: reliably install high -pressure fuel pump on the mounting base of the engine and combine it with mounting holes. For the initial fixing of the high pressure fuel pump, use installation pin or bolts, making sure that it is installed accurately, without displacement or tilt. During the attachment process, be careful to prevent a collision of high pressure fuel pump with a mounting base so as not to damage the parts.

Connect the pipelines: connect the intake fuel, the exhaust fuel and the return fuel of the fuel pump of high pressure in the correct sequence. When connecting, make sure that the pipes are not twisted or curved, and the sealing surfaces are clean and tightly fit. Apply the required amount of sealant to the pipe connections, then tighten the nuts of the joints with the indicated puffing moment to prevent fuel leakage. As a rule, the moment of tightening the joints of the intake and exhaust pipelines of the oil is from [x] n · m to [x] n · m. The specific value depends on the model of the injector pump and the technical characteristics of the pipeline.

Install the adjustment mechanism: Connect the mechanism for adjusting the amount of high pressure fuel pump to the engine control device, making sure that the connection is reliable, and the adjusting rod moves freely. Check the correctness of the initial position of the adjusting mechanism. If necessary, perform the appropriate adjustments to ensure the normal response of the fuel pump to changes in the operating conditions of the engine after installation and achieve an accurate adjustment of the amount of injected fuel.

Debugging and testing: After installation, add clean fuel to the fuel system and perform release operations to remove air from the system. Run the engine, check the operating condition of the high -pressure fuel pump, and also check whether the fuel is injected and there are no leaks. Use professional testing equipment, such as a fuel pressure manometer, a injection time tester, etc., to check and debugging the injection of the fuel pump, the injection time and other parameters to make sure that all parameters comply with the technical requirements of the engine. In the process of debugging, pay attention to the working conditions of the engine, such as speed stability, output power, etc., and accurately tune the fuel pump parameters in accordance with the actual conditions until the engine reaches the best working condition.

3. Common malfunctions and ways to eliminate them

(I) high -pressure fuel pump does not supply fuel

Cause

There is no oil or fuel filter in the fuel tank, which leads to the impossibility of normal fuel supply to high pressure fuel pump. If the fuel filter is not replaced for a long time, impurities will accumulate in it, which can easily cause clogging; If you do not detect an insufficient amount of oil in the fuel tank in time, high -pressure fuel pump may not be able to absorb oil.

The fuel pumping pump is faulty and cannot pump fuel from the fuel tank into the fuel pump of high pressure. Wear or damage to the piston, springs and other parts of the oil pump affects its performance for oil pumping.

The plunger inside the high-pressure fuel pump is stuck and cannot normally make reciprocating movements. This may be due to the impurities in the fuel between the plunger and the plunger's sleeve, which leads to wear or sequel; Or a plunger can count due to poor lubrication due to prolonged use.

The fuel exhaust valve is non -cell or damaged, which leads to a fuel leak and the impossibility of creating sufficient injection pressure. With frequent effects of high pressure, the sealing surface of the exhaust oil valve can wear and scratch, which affects the effectiveness of the compaction.

Bypass

Check the fuel level in the fuel tank and add fuel in a timely manner. At the same time, replace the fuel filter to ensure uniform fuel supply. When replacing the fuel filter, be sure to choose reliable quality products and install it in accordance with the correct installation method.

Repair or replace the oil pump. Disassemble the oil pump and check the wear of the piston, springs and other details. If there is any damage, replace them with new details in time. After installing the oil pumping pump, conduct an oil pump performance check to make sure of its proper operation.

Disassemble the high pressure fuel pump, clean the plunger and a plunger sleeve, remove the pollution. If the plunger is strongly worn or sprinkled, you should replace a couple of new plunges. When installing a plunger pair, be careful so that it is clean and do not allow pollution that gets into it. At the same time, make sure that it is installed correctly, and the plunger moves flexibly.

Check the oil production valve. If it is loosely closed or damaged, replace it with new ones. When installing the exhaust oil valve, pay attention to the purity of the sealing surface and the correct direction of the installation to ensure good tightness.

(II) Fuel supply by the fuel pump is uneven

Cause

The degree of wear of the plunger of each cylinder of the high pressure fuel pump is not the same, which leads to different fuel supply to each cylinder. Due to the differences in the conditions of the operation of each cylinder, the speed of wear of the plunger will also be different. After prolonged operation, uneven oil supply will occur.

The malfunction of the mechanism for adjusting the amount of oil, for example, the sequeling of the adjusting rod and the weakening of the gearbox plug affects the accuracy of adjusting the effective stroke of the plunger. With prolonged use, the adjusting rod can get stuck due to a lack of lubrication, deformation, etc.; The loose connection of the plug with the adjusting lever of the plunger will lead to inaccurate adjustment of the plunger.

The malfunctions of the nozzles, such as clogging of nozzles, unstable pressure pressure, etc., indirectly lead to uneven fuel supply from high -pressure fuel pump. The working condition of the fuel nozzle affects the efficiency of fuel injection, and then on the adjustment of feedback on the supply of fuel fuel of the fuel pump of high pressure.

Bypass

Check the wear of the pluners of each cylinder of the high pressure fuel pump and replace the strongly worn. At the same time, when installing a new plunger, it is necessary to carry out its proper run and debugging to ensure the uniformity of the working characteristics of plungers in each cylinder.

Inspect the mechanism for adjusting the amount of oil, clean the adjusting rod and add the required amount of lubricating oil so that it moves easily. Check the connection between the gear fork and the plunger adjustment lever and tighten it if it is weakened. If necessary, calibrate the mechanism for adjusting the amount of oil to make sure that the accuracy of its adjustment meets the requirements.

Check the fuel nozzles, clean the clogged and adjust the injection pressure to the standard value. If the fuel nozzle is seriously damaged and cannot be repaired, it should be replaced in a timely manner with a new one. After replacing the fuel nozzle, it is necessary to re -regulate the coordinated operation of the fuel pump and the fuel nozzle in order to ensure uniform supply of fuel to each cylinder.

(III) The moment of injection of the fuel pump is inaccurate

Cause

The drive gear of the fuel pump is worn out or incorrectly installed, as a result of which the speed of rotation of the fuel pump camshaft does not correspond to the speed of the crankshaft of the engine, which affects the synchronization of the injection. In the process of prolonged gearing, the gear surface of the leading gear wear out, which leads to a change in the gear ratio; During the installation, if the installation position of the lead gear is inaccurate, the injection moment will also deviate.

The device for adjusting the injection angle is malfunctioning, and the injection time cannot be adjusted accurately. Some high -pressure fuel pumps are equipped with a device for automatic adjustment of the injection. If the sensor, the executive mechanism and other components of the device fail, the injection angle of the injection will not be correctly adjusted in accordance with the operating conditions of the engine.

The camshaft wears out, and the cam profile changes, which affects the movement of the plunger and makes synchronization of the injection inaccurate. In the process of prolonged operation, the camshaft is subjected to periodic shock loads, and the surface of the fist gradually wears out, which affects the time of fuel injection.

Bypass

Check the wear of the gear of the pumping unit. If the wear is strong, replace it with a new one. When installing the lead gear, it must be installed strictly in accordance with the installation marks in order to ensure the correctness of its gear ratio with the crankshaft of the engine and the correspondence of the rotation frequency of the switching shaft of the high -weight fiber of the crankshaft of the engine.

Inspect the device for adjusting the injection angle, check the operating condition of the sensors, executive mechanisms and other components, and in the case of malfunctions, repair or replace them. At the same time, the device for adjusting the injection angle is calibrated so that it can accurately adjust the injection time in accordance with the operating conditions of the engine.

Check the wear of the camshaft. If the camber is strongly worn, replace it with new ones. After replacing the camshaft, it is necessary to accurately adjust the moment of injection of the fuel pump to ensure the exact synchronization of the injection. To adjust and calibrate the injection moment in accordance with the technical requirements of the engine, you can use a professional tester of the injection moment.

4. Repair and maintenance

1. Daily service

Office inspection: before each operation, check the appearance of the high pressure fuel pump for fuel leaks, weakened connecting bolts or damaged tubes. If the fuel leak is detected, find the leakage place in time and eliminate it to avoid overruning fuel and safety threats; Check the tightening of the connecting bolts. If they are weakened, tighten them in time to ensure a reliable installation of the injection pump.

Cleaning: regularly clean the surface of the injector pump from oil, dust and garbage to maintain its cleanliness. In particular, it is necessary to exclude clogging of the intake, exhaust and ventilation holes of the high -pressure fuel pump, which can affect the supply of fuel and heat removal. For cleaning, you can use a clean rag or compressed air, but be careful not to damage the surface coating and components of the fuel pump.

Fuel quality check: Pay attention to the quality of the fuel and regularly check the cleanliness and content of water in the fuel. The use of poor -quality fuel can easily lead to wear and clogging of the internal parts of the fuel pump. If impurities or water are found in the fuel, fuel should be replaced in a timely manner, and the fuel filter should be cleaned or replaced. When refueling, choose a regular gas station to be sure of the quality of the fuel.

(II) regular maintenance

Replacing the fuel filter: regularly change the fuel filter in accordance with the prescribed maintenance cycle. Typically, the fuel filter must be replaced every [x] hours of work or every [x] months. The specific period depends on the operating conditions of the engine and the quality of the fuel. When replacing the fuel filter, be sure to choose a product corresponding to a high pressure fuel pump, and install it in accordance with the correct installation method to provide the filter filter effect.

Maintenance of the lubricant system: Check the high -pressure fuel lubrication system to make sure of sufficient lubricating oil and its good quality. The plunger, the distribution shaft and other components inside the fuel pump require good lubrication to reduce wear and extend the service life. Change lubricating oil regularly and clean the lubricant filter to prevent pollution from getting into the lubrication system. At the same time, check if there are leaks, blockages, etc. In a lubricant. If there are any problems, eliminate them in a timely manner.

Determination and adjustment of fuel injection: Use a pressure gauge to determine the pressure of fuel injection by a fuel pump through regular intervals. If the injection pressure does not correspond to the specified value, it should be adjusted in a timely manner. Too high or too low injection pressure will affect the effectiveness of combustion and engine performance. When adjusting the injection pressure, follow the technical requirements for the injection pump and use professional tools to ensure the accuracy of adjustment.

Calibration of injection time: regularly calibrate the fuel pump injection time to ensure the exact injection time. To adjust the injection moment in accordance with the operating conditions of the engine and technical parameters, professional equipment can be used, such as the injection angle of the injection. Inaccurate adjustment of the injection moment will lead to a decrease in the engine power, an increase in fuel consumption, excessive emissions and other problems, so it is very important to regularly calibrate the injection moment.

(III) precautions during maintenance

Use original details: During the maintenance, be sure to use the original parts of the high -pressure fuel pump that meet the standards of Carter engines, such as plunger pairs, oil supply valves, filters, etc. The quality of fake and non -quality components cannot be guaranteed, which can lead to a decrease in the productivity of the fuel pump of high pressure, frequent refusals and even Damage to the engine, which will lead to huge economic losses for users.

Follow the working procedures: maintenance personnel should strictly comply with the maintenance of the fuel pump of the high pressure of the Carter engine, use the tools and standardize working procedures. For example, when disassembling and installing the components of high -pressure fuel pump, be careful not to damage the components; When adjusting the pressure and injection time, follow the prescribed methods and steps to ensure the accuracy of adjustment. Incorrect operation can lead to the appearance of new malfunctions and influence the normal use of the fuel pump.

Detect records: lead detailed notes about the time, content, replaced details and testing data of each maintenance. Creating a full file for repair and maintenance of equipment will help to monitor the use of the fuel pump, timely detect potential problems, provide reference information for subsequent repair and maintenance work, as well as facilitate the analysis and assessment of the service life of equipment and maintenance costs.

5. After -sales service

1. After -sales service team

We have a professional and effective after -sales team. All team members have rich experience in serving Carter engines and are familiar with the structure and principle of operation of carbon injection pumps of Carter. After thorough technical preparation and evaluation, after -sales maintenance engineers can quickly and accurately diagnose malfunctions in high -pressure fuel pumps and related components and offer practical solutions. Whether it is a product installation manual, elimination of malfunctions and maintenance or technical advice, we can provide customers with professional and attentive services.

(II) Warranty service

We provide [x] years of guaranteeing quality of products. During the warranty period, if the high pressure fuel pump is out of order due to problems with product quality, we will provide customers with free repair or replacement services and take on the appropriate transportation costs. Clients only need to call the hotline of after -sales service, and we will organize the speedy arrival of specialists to the client to find out the cause of the malfunction, check the product information, determine the solution and speedy work on repair or replacement to guarantee the speedy resumption of the normal operation of the client’s equipment.

(III) Technical support

Online consultations: a special online platform has been created for technical consultations, where customers can at any time ask questions about the use, maintenance, elimination of malfunctions, etc. The fuel pump through the official website, the WeChat public account and other channels. Our experts will quickly respond to customer requests during working hours and provide them with detailed and accurate technical recommendations and solutions based on professional knowledge and rich experience. For some common problems, we also provide an online knowledge base where customers can independently look for the necessary information and quickly get solutions.

Place training: depending on the needs of the customer, professional technical specialists can go to the object for free training of operators and the customer service personnel. The content of the learning includes the principles of the design of the fuel pump of high pressure, the methods of installation and dismantling, daily maintenance points, general methods for diagnosing and eliminating malfunctions, etc. Using demonstrations on the ground, practical recommendations for operation and other methods, we help customers improve the skills of equipment and maintenance skills, increase their ability to independently solve problems, reduce the amount of refusal equipment and increase the efficiency and reliability of its use.

4. Quick response

We have created a comprehensive mechanism for response after sales service. As soon as the client reports on the problem, we contact the client within [x] hours to learn more about the situation. In the event of problems requiring repairs on the spot, we will organize the leave of the nearest specialist in after -sales service to the place in the shortest possible time, depending on the location of the client. In general, we arrive at the place for 24 hours in China. For customers exporting to foreign regions, such as Russia, we will closely cooperate with local partners in order to guarantee arrival at the place for service within 48-72 hours, minimize the economic losses caused to customers by the refusal of equipment, and guarantee that the customer construction will not be affected.

6. Advantages of export to Russia

1. Adaptation to difficult working conditions in Russia

Optimized frost resistance indicators: in Russia long and cold winters, while in some areas the lowest temperature drops below -50 ° C. In the process of design and production of our high -pressure fuel pump for Carter engines, we fully take into account the influence of the low -temperature environment on the equipment. Choose materials with excellent frost resistance so that high-pressure fuel pump can work normally at low temperatures, and the fuel does not harden and its fluidity does not deteriorate due to low temperatures, which ensures normal starting and operating the engine. At the same time, the seals and lubrication systems of the fuel pump were specially optimized to increase its reliability and durability in low temperatures.

Resistance to poor -quality fuel: the quality of fuel in some parts of Russia is heterogeneous, it has a high sulfur content and many impurities. Our high -pressure fuel pumps have excellent resistance to fuel impurities and corrosion. Due to the optimization of the design of the internal structure and the use of corrosion-resistant materials for the manufacture of key components, wear and corrosion of fuel impurities on high-pressure fuel pumps are effectively reduced. Even when using poor -quality fuel, they can maintain stable work and reduce the number of failures caused by fuel quality problems, providing Russian clients with reliable user experience.

(II) comply with Russian certification standards

We attach great importance to the quality of products and conformity. Our Carter Engine injection pumps passed strict tests of the relevant Russian certification bodies and received a number of certificates of certification necessary for access to the Russian market, such as GOST certification. This means that our products are fully consistent with Russian security standards, quality and ecology, and all aspects - from the choice of materials, the production process to the operational characteristics of products - are strictly controlled. By purchasing and using our products, Russian buyers may not worry about various risks associated with the inconsistency of products to local standards, such as products reviews, fines, etc., and can use our products with confidence.

There are many models of Caterpillar engines, and below is entry information on their classification:

Industrial diesel engines

Small engine

C1.1: Nominal power 14.4-18.4 kW, speed 2200-3400 rpm.

C1.5: Nominal power 18.4-30.0 kW, speed 2100-3000 rpm.

C2.2: The maximum power can reach 50 kW.

Middle engine

C7.1: The rated capacity is 112–162 kW, speed of 1950–2200 rpm, suitable for small trucks, buses, generator installations, construction equipment, agricultural machinery and other areas of application.

C9 Acert: usually used in some medium construction machines, generator installations and other equipment. It has a large output capacity and can satisfy various operational needs.

C11 Acert: This is a high -power model among medium -sized engines suitable for medium -sized industrial equipment and vehicles with higher power requirements.

Large engine

C13 Acert: Power range 287–388 kW, suitable for heavy trucks, excavators, drilling rigs, crushers and other equipment.

C15 Acert: The power is from 328 to 403 kW at a certain speed and is widely used in construction equipment, trucks, ships and other areas.

C18 Acert: It uses advanced turbocharging technologies and intermediate air cooling. For example, the wheel bulldozer Caterpillar 834h is equipped with this engine.

C27: Suitable for large -sized construction equipment, such as excavators, loaders and rollers, with high power.

C32: One of the most powerful diesel engines that are currently available can set in motion heavy equipment and large ships.

Engines for construction equipment

Engine for a small excavator

C3.6: The rated power is 55–100 kW, speed 2000–2400 rpm, suitable for small excavators, is characterized by good fuel efficiency and stable output power.

C4.4 Acert: The maximum power of 129.4 kW is widely used in small excavators, can satisfy the operational needs of small excavators in various working conditions.

Engines for medium and large excavators: C9.3/C13 Acert. These two engines are common power configurations for medium and large Caterpillar excavators and can provide excavators with a high digging force and efficiency.

Fire pump diesel engine

3406C: The maximum power of 359 kW is widely used in fire protection, can provide a stable output capacity for fire pumps, guaranteeing the uninterrupted course of fire operations.

3412C: maximum power 551 kW, which is enough to meet the needs of large firefighter equipment.

3508: The maximum power is 794 kW, suitable for large fire pumps, is highly reliable and stable.

3512: With a maximum capacity of 1193 kW, it can provide powerful energy support for large fire pumps and guarantee the effective performance of fire extinguishing.

3516: Having the maximum capacity of 1480 kW, this is the largest model among diesel engines of firepile fire pumps and can be used to extinguish fires in large areas.

Other models

330D2L: a 200 kW diesel engine and a maximum torque of 1000 nm. This is a modernized version of the line 6-cylinder engine Caterpillar 988C, which is usually used in some medium-sized Caterpillar construction machines.

D398-TA: D denotes a diesel engine, 3 indicates the serial number of the engine 300, 98 denotes 12 cylinders, and TA denotes the type of turbocharger operating on exhaust gases, which is usually used in large industrial equipment or ship power plants.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive