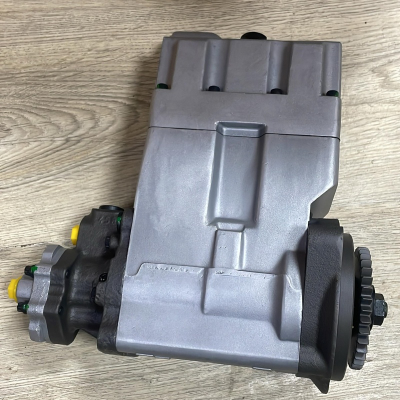

Shantui 16y-18-00013 Segment bolt and gale nut block

1 、 High strength and durability : are made of high -quality steels that can withstand significant mechanical loads. This allows them to work steadily in the conditions of intensive operation and loaders, where strong traction, pressure forces arise. They have highness and resistance to corrosion, which guarantees a long service life.

2 、 exact compatibility : specially designed for Shantui SD16 models and the corresponding wheel loaders. They have the exact dimensions and shapes that perfectly coincide with the rest of the design details, providing a reliable connection and non -circuit work as part of the machine.

The convenience of installation and dismantling : The balanced design of sectional bolts and gearbox blocks allows you to easily and quickly perform installation and dismantling operations. This reduces the time of maintenance and repair, increases the efficiency of technical personnel and reduces the downtime of equipment.

Представление продукта

Product Details

Specifications: For example, the bolt with model number 16Y-18-00013 may have a specification of M22×1.5×70.

Material: Generally, high-strength alloy steel and other materials are used to meet the high-strength use requirements of bulldozers under complex working conditions, with high strength, toughness and fatigue resistance.

Function: Mainly used to connect the tooth block of Shantui SD16 bulldozer with other components, so that the tooth block can be firmly fixed in the corresponding position, ensuring the normal operation of the bulldozer's walking system, drive system, etc., transmitting power and bearing various forces.

Features: The surface is treated with rust prevention, such as galvanizing, blackening, etc., to improve the corrosion resistance of the bolt and extend its service life. It has high-precision thread processing to ensure good cooperation with nuts or threaded holes and achieve reliable fastening connection.

Installation method

Preparation before installation:

Cleaning parts: Use cleaning agents and sandpaper and other tools to remove dirt, rust, oil and other impurities on the tooth block, installation site and bolt surface to ensure that the installation surface is clean and flat.

Check the parts: carefully check whether the gear block bolts have cracks, deformation, thread damage and other defects, and check whether the gear block and the matching parts are damaged, worn, etc. If there are any problems, replace them in time.

Prepare tools: prepare suitable installation tools, such as wrenches and torque wrenches of corresponding sizes.

Installation process:

Insert the bolts: carefully insert the bolts into the mounting holes of the gear block and the corresponding parts to ensure that the bolts can pass smoothly and do not damage the threads.

Install washers: install flat washers and spring washers as needed. Generally, flat washers are placed on the workpiece side and spring washers are placed above the flat washers to disperse the pressure and prevent loosening.

Preliminary tightening: Use a wrench to screw the nut into the bolt for preliminary tightening, but do not tighten it to the final torque. It can be done in a diagonal alternating manner to make the bolts evenly stressed.

Final tightening: Use a torque wrench to perform final tightening according to the specified torque value to ensure that the bolts reach the tightness required by the design. The torque values of SD16 gear block bolts of different specifications are different, and you need to refer to the relevant technical manual.

Common faults

Loose bolts:

Reason: The bulldozer vibrates greatly during operation, and long-term vibration will gradually loosen the bolts; the bolts are not tightened according to the specified torque value during installation, or the washers used are damaged or ineffective, and cannot prevent loosening.

Impact: Loose bolts will cause the tooth block to be loosely connected, affecting the normal operation of the bulldozer. In severe cases, the tooth block may fall off, causing equipment damage and safety accidents.

Broken bolts:

Reason: The tooth block is subjected to excessive impact force or alternating load during operation, which exceeds the bearing capacity of the bolt; the bolt material has defects, such as cracks and inclusions inside; excessive tightening during installation causes the bolt to bear excessive preload.

Impact: Broken bolts will cause the tooth block to lose its fixation, causing the bulldozer's walking, driving and other systems to malfunction, unable to work normally, and may even cause damage to other components.

Thread slippage:

Reason: The matching accuracy between the bolt and the nut or threaded hole is not enough, or the thread is damaged during installation; the thread surface is severely worn during use, resulting in an increase in the matching clearance.

Impact: Thread slippage will make the bolt unable to be effectively tightened, prone to loosening, and reduce the reliability of the connection. It is necessary to replace the bolt or repair the threaded hole in time.

Basic Info.

Model NO.

16Y-18-00013

Type

Bolt and Nut Tooth Block

Application

Construction Machinery Parts

Certification

CE

Condition

New

Product Name

Bolt and Nut Tooth Block

MOQ

1PC

Sample Order

Support

Payment Method

Tt Wesrern.Union Alipay Wechat Paypal. ******

Delivery Time

Within 2-5 Working Days

After Sales Service

Online Guide

Quality

High Quality

Color

as Picture Show

Warrenty

Six Months

Place of Origin

China

Model

Wheel Loader

Packing

Carton Box

OEM

OEM and Genuine All Avaliable

Export Method

EXW DDP DAP Fob CIF

Package

Stand Export Box

Transport Package

Stand Export Box

Origin

China

Production Capacity

1000 Sets/Months

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) Competitive price: The concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) Service Team: Firstly, our sales managers are available 24 hours a day, ready to answer your questions at any time. Secondly, a professional technical service team with senior technicians, ready to provide support services to users and dealers. Most problems can be resolved within 24 hours.

4) Fast Delivery: Generally, we can deliver within 10 working days at the factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you in the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve problems without any hesitation, supply you with all-round