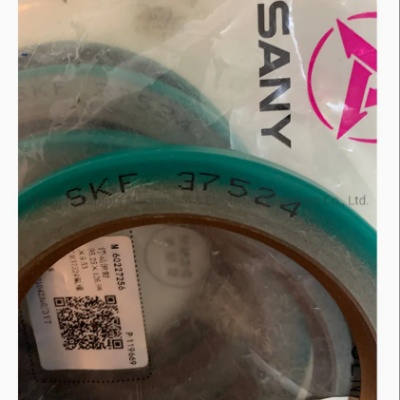

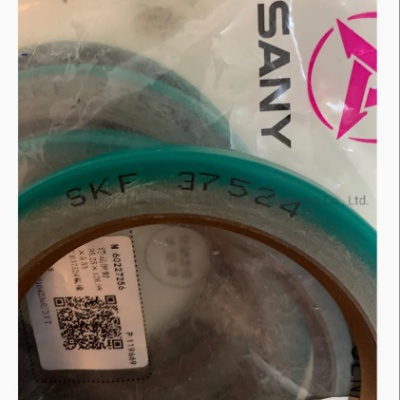

Sany 60227256 seals

1. Reliable sealing: a special structure and materials resistant to high pressure, temperature changes and preventing a leakage of the medium.

2. Super -resistant: after special processing, it becomes wear -resistant, resistant to aging, vibrations and impacts, and also has a long service life.

3. Good adaptation: sets up in accordance with the components of the vehicle model, the exact size, is easy to install and adapts to various vehicles.

Product representation

Detailed product information

Various types: including oil seals, sealing rings, seals of cylinder sleeves, dustproof seals, etc. For example, Cummins QSK19 3085867 Cummins Cupid Sany Str55c Commins.

The main functions: prevention of leakage of lubricating oil, hydraulic oil, etc., preventing external pollution, dust, etc., protection of internal parts, such as truck engines, gearboxes, axis, ensuring normal operation of various details, reduction wear and extension of the equipment service life.

Excellent material: usually made of rubber, fluorine, silicone rubber, polyurethane and other materials, has good oil resistance, corrosion resistance, wear resistance, resistance to high temperatures and sealing properties, can adapt to harsh working conditions in mines.

Complete technical characteristics: for various models of Sany career dump trucks, such as SY3515, SY3630, etc., there are seals of various specifications and sizes that meet the requirements for sealing various components.

Stages of installation

Preparation: Make sure that the working environment is clean to prevent dust and dirt on the seals; Select the appropriate tools in accordance with the compaction model, such as wrenches, heads, special mounting tools, etc.; Check if the seals are damaged, whether they are deformed or not aged, and if so, replace them with new ones; Check if the surface of the established part is clean and even, without defects, such as rust, burrs, scratches, etc.

Remove the old seal: turn off the power or power of the concomitant truck systems, weaken the bolts, nuts and other connections that fix the seal using special tools; Carefully remove the old seal, trying not to damage the surface of the installation site of the sealing ring and the adjacent parts.

Cleaning and inspection: use a detergent or clean soft cloth to gently wipe the surface of the installation part of the seal to remove oil, pollution, rust, etc.; Check if there are problems such as wear, deformation, cracks, etc. on the installation details. If necessary, timely repair or replace the corresponding parts in a timely manner; Check whether the size and shape of the new seal of the installation part correspond to, and whether key details, such as the sealing edge, are intact.

Install new seals: apply the corresponding amount of lubrication or special installation lubrication to the surface of a new seal to facilitate the installation and prevent damage to the seal; Correctly place a new seal at the installation site and make sure that it is installed in the right direction. For seals with the requirements for the direction such as oil seals, pay special attention to the direction of the edge; Use special tools to evenly and slowly press or push the seal to the installation position to avoid tilt, twisting or deformation of the seal. For example, use a sleeve to carefully knock on the oil seal and fit it under the shaft or hole.

Checking and testing: After installation, check if there is a seal in place and there are no deviations or rise. Gently press or pull the seal to check whether it is installed reliably. Connect the appropriate parts and pipelines, run the truck for a trial launch, check if there are leaks in the sealing part, and observe for some time to make sure of the good seal efficiency.

Common malfunctions

Leak: aging, wear and damage to the seals, for example, wear of the oil of oil seal, aging and breakdown of sealing rings; Incorrect installation, for example, the seals are installed at an angle, are not installed in place or bolts are not tightened; harsh working conditions, long -term exposure to high temperature, high pressure, high vibration, etc., leading to a deterioration in the characteristics of the seal; Average problems, for example, deterioration in the quality of lubricant or hydraulic oil, impurities, etc., which cause corrosion or wear of seals.

Deformation: excessive external effort, squeezing or blows during installation; The temperature of the working environment is too high or too low, which leads to a change in the properties of the material of the seal; The seal is subjected to uneven pressure or stress.

Hardening or fucker: prolonged contact with the working environment, chemical reaction; improper storage or operation conditions, such as the effects of sunlight, contact with chemical solvents, etc.; Long -term use, natural aging of the seal.

Adhesion: insufficient lubrication between the seal and the mounting surface; Certain components in the working environment lead to the adherence adherence to the surface of the component; The seal sticks to the surrounding components due to long-term downtime.

After -sales service

Consulting Service: Sany Heavy Industry has a special hot service line. Users can call the hotline to consult on issues related to seals such as the choice of product, installation methods, troubleshooting, etc. Professional specialists will give answers.

Supply of accessories: we have a complete system of deliveries of accessories, and we can supply various types of seals for the Sany career dump trucks in a timely manner, guaranteeing that users will be able to quickly get original accessories when they need to replace the seals.

Maintenance: throughout the country and even around the world, there are many posts after -sales service, equipped with professional maintenance personnel. In case of failure of the seal, you can contact the local after -sales service center, and maintenance specialists will arrive in time in time for the repair or replacement of the seal.

Quality guarantee: a certain period of quality guaranteeing is provided for sealing products. During the warranty period, if the seal fails due to quality problems, Sany Heavy Industry will replace or repair it for the user for free.

Learning services: providing users of training on installation, maintenance and care of seals to increase operation skills and level of user service, as well as reduce the number of seals caused by improper operation.

The selection of seals suitable for Sany career dump trucks requires a comprehensive consideration of many aspects, namely:

Clarify information about the car model and details

Determine the vehicle model: Sany career dump trucks have many models, for example, SY3515, SY3630, StR55C, etc. Various models of trucks can have different specifications and compaction requirements. First, it is necessary to accurately determine the model of the vehicle.

Understand the location of the components: to determine the specific components that require seals, such as the engine, gearbox, axis, cylinder, etc. Various components have different compaction requirements. For example, the engine may require oil seals and sealing rings for sealing oil and coolant, while the cylinder requires piston seals, dustproof seals, etc.

Consider the factors of the working environment

Temperature: Environmental temperature in the production area varies greatly. At high seals, the seals can soften and deform, and at low temperatures they can harden and crack. When working at high temperatures, you can choose seals from materials resistant to high temperatures, for example, fluoride; In conditions of low temperatures, seals with good resistance to low temperatures, for example, of silicone rubber are needed.

Pressure: choose depending on the pressure that the sealing part is subjected to. For example, for a high-pressure hydraulic system, it is necessary to choose seals with high pressure resistance, such as the sealing rings of the Y-type and V-type. For details subject to lower pressure, sealing rings may meet the requirements.

Dust and impurities: in the prey zone there is a lot of dust, which can easily penetrate into sealing parts and cause wear and leakage. You can choose seals with dust gathering edges or more complex sealing structures, such as two -year -old oil seals, piston seals with dustproof rings, etc.

Pay attention to the material of the seal.

Oil resistance: seals that are in contact with lubricating oil and hydraulic oil should have good oil resistance. Nitrilum rubber is widely used oil -resistant material and can be used in most oil media. For special oils, such as oils containing aromatic hydrocarbons, more modern oil -resistant materials, such as fluoride, may require.

Wear resistance: compaction of the moving parts, such as piston seals and oil oil seals, should be made of materials with good wear resistance, such as polyurethane, polytetrafor -ethnic, etc., to increase the service life of the seals.

Corrosion resistance: if the working environment of the truck contains caustic media or the oil or coolant used is caustic, the seals should be corrosion-resistant. Poftorcacus, EPDM taccard, etc. They have good corrosion resistance.

Compliance with the characteristics and size of the seals

Dimension measurement: accurately measure the installation dimensions of the sealing part, including the inner diameter, external diameter, width, thickness, etc., to make sure that the selected seal size exactly corresponds to the installation part. For example, the inner diameter of the oil seal should correspond to the diameter of the shaft, and the outer diameter should be the size of the mounting hole.

Requirements for tolerances: Pay attention to the range of tolerance tolerance to comply with the requirements of the accuracy of the installation of the components of the truck. Too large or too small tolerances can affect the effect of compaction and ease of installation.

Check out the recommendations and standards of the original manufacturer.

Contact the leadership: contact the user management, maintenance management and other Sany career materials that usually contain recommended seals, technical characteristics, materials and other information. The choice in accordance with original factory standards can guarantee compatibility and adaptability of seals to the vehicle.

Contact the manufacturer: contact directly with the SANY after -sales service or technical support personnel to get professional consultation consultation. They can provide accurate recommendations based on specific vehicle conditions.

Consider the brand and quality

Choose well -known brands: give preference to seals with good reputation and high popularity in the market, such as Parker, NOK, etc. The seals of these brands, usually more reliable quality, with a more stringent process of production and quality control, as well as with the best performance characteristics and service life.

Quality certification: check whether the seal of the corresponding quality certification has, for example, certification of the ISO9001 quality management system, certification of the ISO/TS16949 automotive industry management system, etc. The quality of certified products deserves more trust.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive